- Products

- Industries

- About

- Our Specials

- Media

- Resources

- Contact

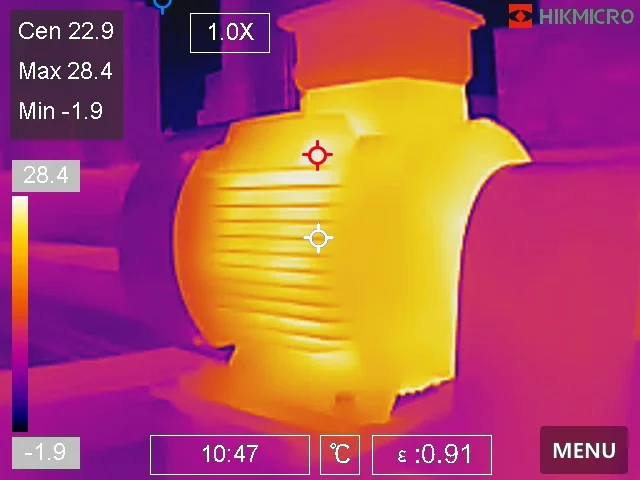

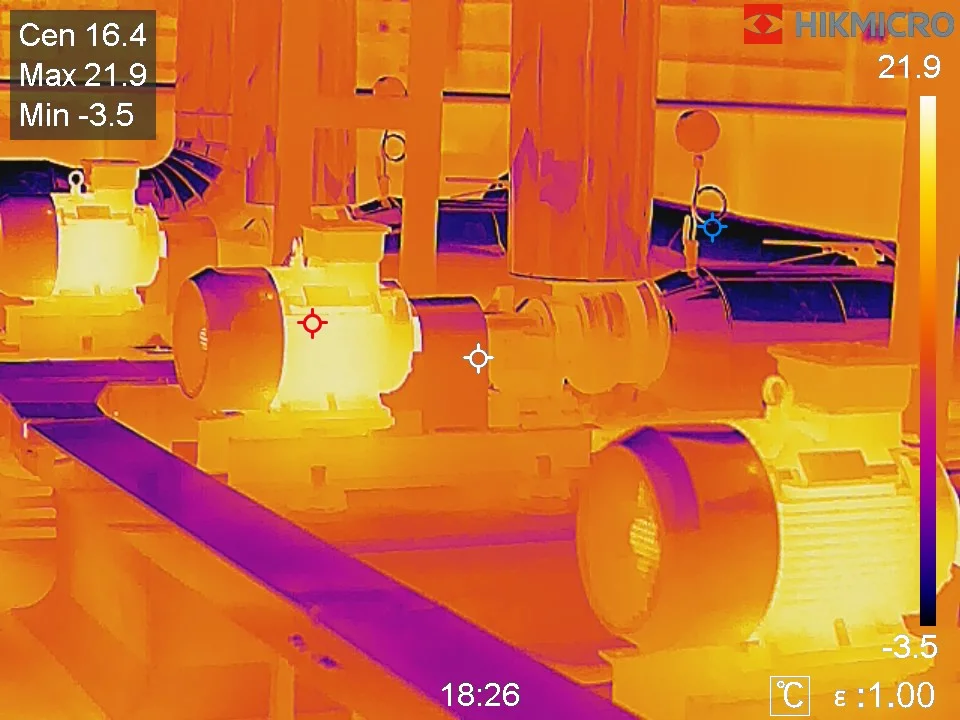

Thermal imaging devices detect different levels of heat based on the infrared waves released by objects. Professional thermal imaging cameras can identify precise differences in temperature to generate a detailed image of hot areas with the exact temperature measurements. The differences in temperature reading can be utilized to discover potential faults in malfunctioning equipment and in systems that have been improperly installed.

Majority of companies in manufacturing are often required to be operating 24/7; taking equipment off-line for regular maintenance can result in extremely high costs and loss of valuable time. Consistency and dependability can be increased when thermal imaging is used as part of the inspection and maintenance processes and in turn, downtime and maintenance costs can both be drastically reduced. Thermal imaging allows heat irregularities in electrical, mechanical, and process equipment to be detected early before a failure occurs. This minimizes the risk of failure, interruption to business and potentially other unforeseen dangerous conditions.

View Thermal Cameras

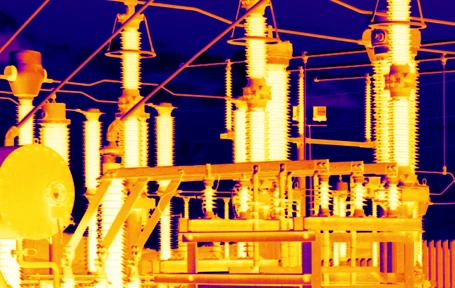

Electrical distributors support millions of users on a daily basis, and figuring out potential failures in the lines and in the metering systems is crucial for providing consistent quality service to customers. Heating up is common in circuit breakers, switches and transformers before failure. Thermal cameras are ideal to detect hotspots, measure temperature and allow repairs to be scheduled before failures occur. Thermal imaging devices are excellent for safety inspections, and also enable proactive inspections, monitoring and planning for routine maintenance.

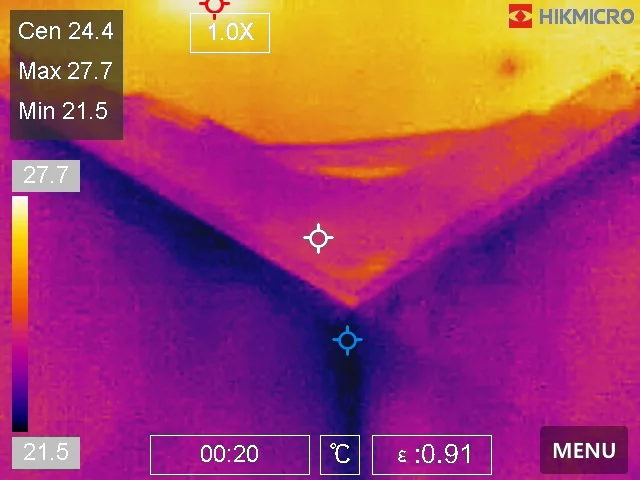

View Thermal CamerasThermal imaging is essential in home building for water leaks, air leaks, indoor air quality, humidity and thermal bridging. Thermal imaging equipment assist to ensure quality, minimize rework and costly call-backs. These are also useful for leaky plumbing, roofs with pest infections, walls, ceilings, floors, windows, doors, basement and structural elements. Thermal imaging cameras in particular help with faults that are hard to see with the naked eye.

View Thermal Cameras

Thermal imaging equipment can be utilized as a diagnostic and preventative tool for building maintenance and is essential in HVAC repairs and maintenance. These tools help diagnose HVAC system issues before they become significant problems by displaying the infrared energy emitted by the object. The temperature of the object determines the level of infrared energy emitted and this allows thermal cameras to display the exact hot and cold areas and use that information to fix the problems accordingly. Top issues that thermal imaging can help identify include:

Thermal imaging can provide expediency, efficiency and a non-invasive method of inspection and evaluation in vehicle components. These devices enable technicians to determine if further work is necessary to be conducted, therefore speeding up the repair process. Other benefits of thermal imaging inspection include; assisting in diagnostics, help spot defects and trouble areas, produce status reports on systems and provide verification throughout the repair process

View Thermal Cameras

By incorporating thermography, you improve quality assurance and minimize production losses during production of high-grade steels. Thermal imaging can useful to monitor surface temperature, the outer shell of ladles and the torpedo cars to prevent idle time and accidents. Monitoring with thermal cameras can also enable early detection of week point on crane ropes in real-time. Benefits of using thermography include:

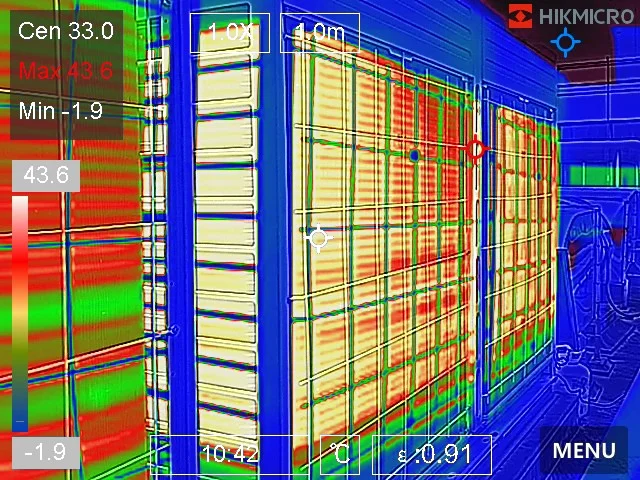

Thermal imaging makes it possible for operators to conduct inspections in total safety. Faulty electric utilities can be extremely harmful for inhabitants, as well as, any type of energy loss or abnormal temperature in electric utilities can be very uneconomical. The innovation of thermal imagers into utility maintenance and repair has transformed operations, ensuring increased efficiency and sustainability, but most importantly prioritizing safety. Unearthing electrical faults with thermal imaging pinpoints but not limited to; overloaded circuits, faulty connections and damaged components. Thermal imaging equipment is key for disaster management and emergency response.

Conduct an entire utility inspection without halting the supply of electricity!

View Thermal Cameras

Power line and utility thermal inspections are designed to locate electrical problems and assist utilities to eliminate failures in the transmission, distribution and substation systems. The use of thermography cameras for power line inspections facilitates the quickest and most accurate method of inspections.

Thermal imaging is useful for electrical system safety, reliability and saves the utility company hundreds of Rands by conducting maintenance during regular business hours without interrupting production thus preventing major power outages. The thermal imaging cameras help locate problems on cutouts, substation getaway structures and poor or failed connections.

This technology is highly beneficial for checking construction quality. The benefits of detecting hot spots early include the extension of life of well-functioning equipment, preventing equipment failures that can result in wide spread outages and most importantly, the reduction of costs through maintenance as opposed to replacement of damaged equipment.

View Thermal Cameras